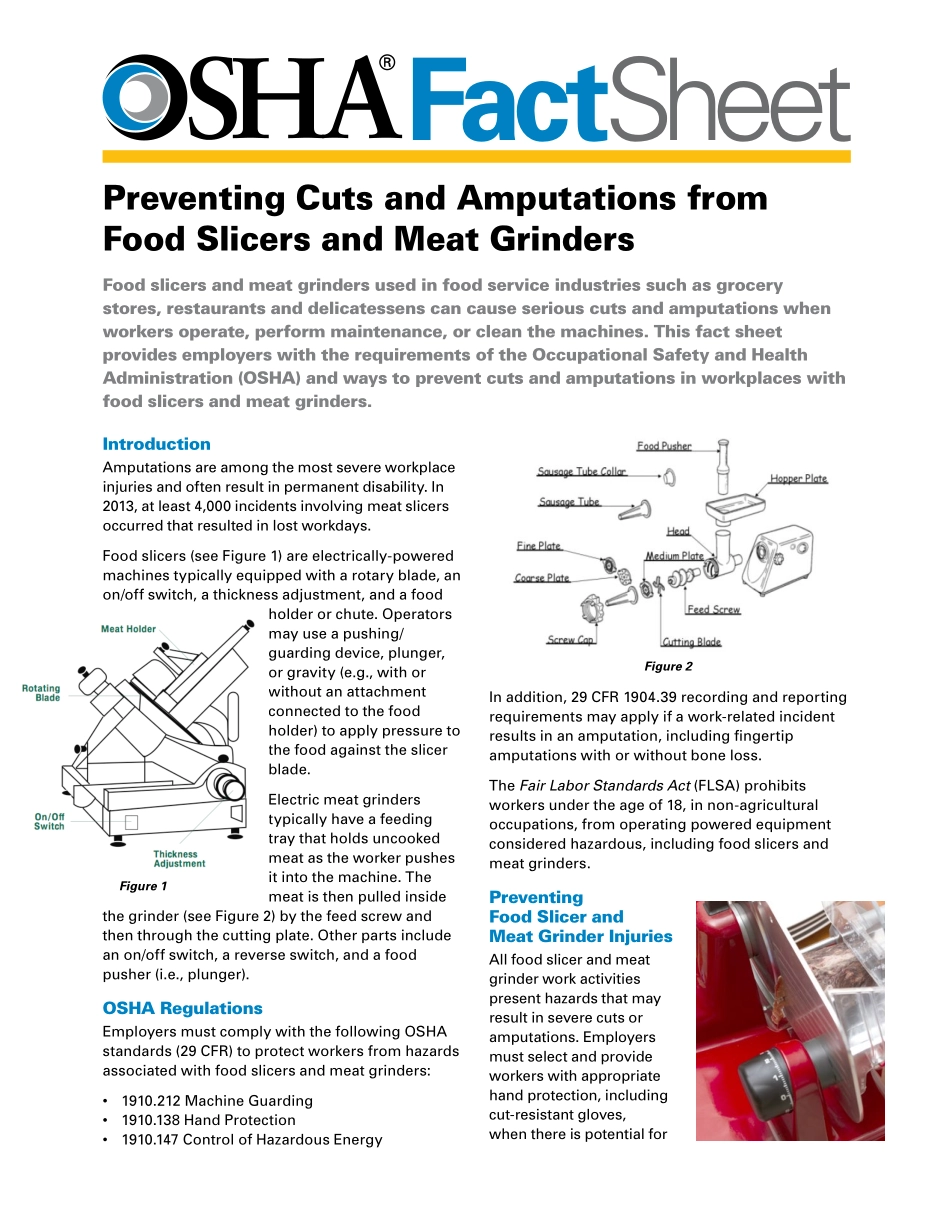

FactSheetPreventingCutsandAmputationsfromFoodSlicersandMeatGrindersFoodslicersandmeatgrindersusedinfoodserviceindustriessuchasgrocerystores,restaurantsanddelicatessenscancauseseriouscutsandamputationswhenworkersoperate,performmaintenance,orcleanthemachines.ThisfactsheetprovidesemployerswiththerequirementsoftheOccupationalSafetyandHealthAdministration(OSHA)andwaystopreventcutsandamputationsinworkplaceswithfoodslicersandmeatgrinders.IntroductionAmputationsareamongthemostsevereworkplaceinjuriesandoftenresultinpermanentdisability.In2013,atleast4,000incidentsinvolvingmeatslicersoccurredthatresultedinlostworkdays.Foodslicers(seeFigure1)areelectrically-poweredmachinestypicallyequippedwitharotaryblade,anon/offswitch,athicknessadjustment,andafoodholderorchute.Operatorsmayuseapushing/guardingdevice,plunger,orgravity(e.g.,withorwithoutanattachmentconnectedtothefoodholder)toapplypressuretothefoodagainsttheslicerblade.Electricmeatgrinderstypicallyhaveafeedingtraythatholdsuncookedmeatastheworkerpushesitintothemachine.Themeatisthenpulledinsidethegrinder(seeFigure2)bythefeedscrewandthenthroughthecuttingplate.Otherpartsincludeanon/offswitch,areverseswitch,andafoodpusher(i.e.,plunger).OSHARegulationsEmployersmustcomplywiththefollowingOSHAstandards(29CFR)toprotectworkersfromhazardsassociatedwithfoodslicersandmeatgrinders:•1910.212MachineGuarding•1910.138HandProtection•1910.147ControlofHazardousEnergyInaddition,29CFR1904.39recordingandreportingrequirementsmayapplyifawork-relatedincidentresultsinanamputation,includingfingertipamputationswithorwithoutboneloss.TheFairLaborStandardsAct(FLSA)prohibitsworkersundertheageof18,innon-agriculturaloccupations,fromoperatingpoweredequipmentconsideredhazardous,includingfoodslicersandmeatgrinders.PreventingFoodSlicerandMeatGrinderInjuriesAllfoodslicerandmeatgrinderworkactivitiespresenthazardsthatmayresultinseverecutsoramputations.Employersmustselectandprovideworkerswithappropriatehandprotection,includingcut-resistantgloves,whenthereispotentialforFigure1Figure2workers’handstocomeincontactwiththeblades.Safeworkproceduresalsoincludefullyretracting(zero)thebladewhentheslicerisnotinuseorwhencleaningtheblade.Employersshouldprovidemeatgrinderoperatorswithproperlysizedplungerstoeliminatetheneedfortheirhandstoenterthefeedthroatduringoperation.Operatingandcleaningfoodslicersandmeatgrindersaretwoseparateworkactivitiesthatmayrequireadditionalhazardcontrols.PreventingWorkerInjuriesWhenUsingaFoodSlicerWhenfoodslicersareinuse,orturnedoffbutstillenergized,thetopandbottomoftheslicerarehazardousareaswhereworkers’fingersandhandsmaycontacttheblade,causingseriouscutsoramputations.Rotarybladefoodslicersmustbeusedwithguardsthatcovertheunusedportionsoftheslicerbladeonboththetopandbottomoftheslicer.Employersshouldbuyslicersalreadyequippedwithafeedingattachmentonthefoodholderslidingmechanismorpurchasethisattachmentseparatelyandinstallitbeforeuse.Workertrainingtopicsshouldincludeto:•Neverputahandbehindthefoodchuteguard.•Neverplacefoodintotheslicerbyhand-feedingorhandpressure.•Useapushing/guardingdevicewithchute-fedslicers.•Useplungerstofeedfoodintochute-fedslicersorusethefeedingattachmentlocatedonthefoodholder.•Turnoffthefoodslicerwhenchangingfoods.•Keephandsoutofthedangerzoneonthebackofthebladewheretheslicedfoodexits.•Turnoffandunplugslicerswhennotinuseorwhenleftunatte...