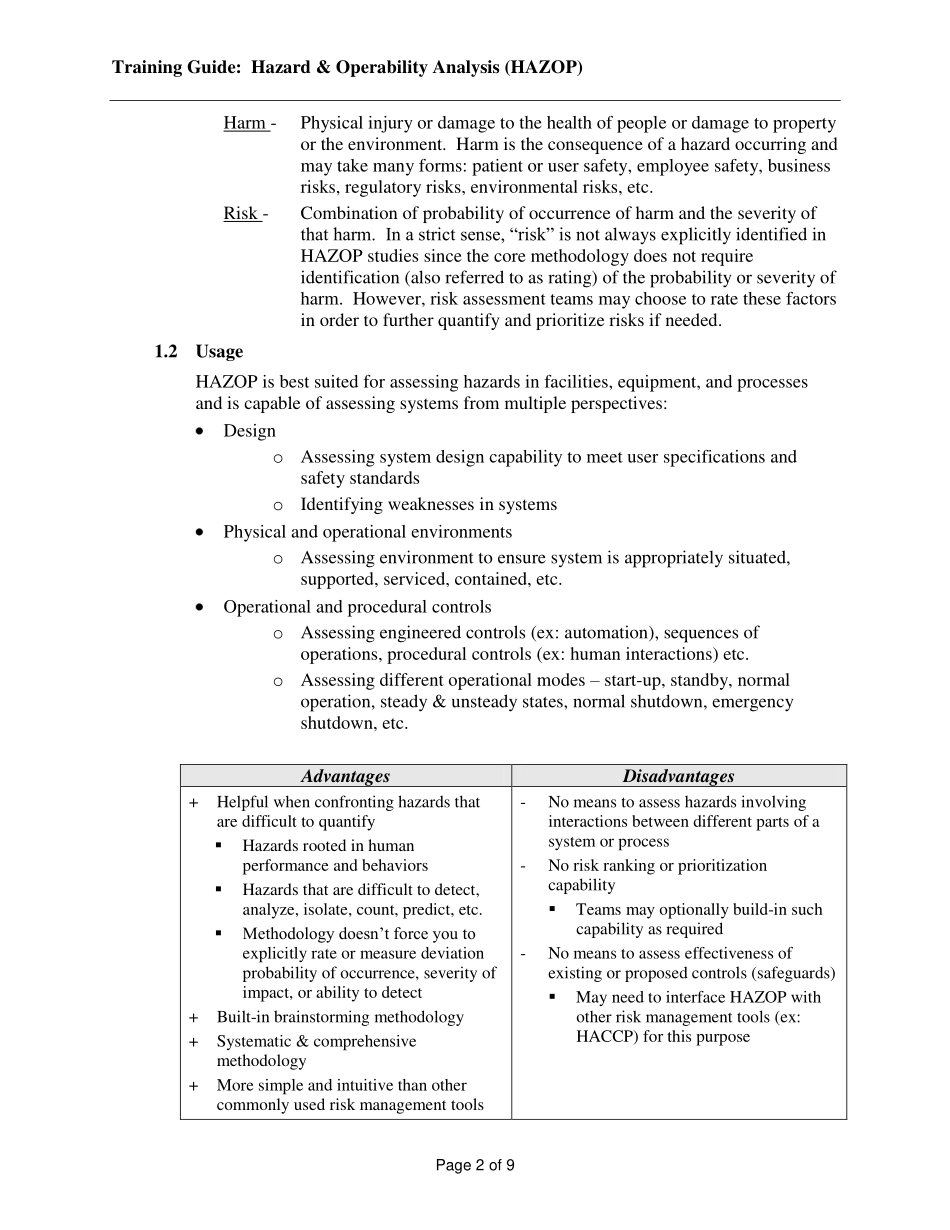

ManufacturingTechnologyCommittee–RiskManagementWorkingGroupRiskManagementTrainingGuidesHazard&OperabilityAnalysis(HAZOP)Page1of91OverviewHazardandOperabilityAnalysis(HAZOP)isastructuredandsystematictechniqueforsystemexaminationandriskmanagement.Inparticular,HAZOPisoftenusedasatechniqueforidentifyingpotentialhazardsinasystemandidentifyingoperabilityproblemslikelytoleadtononconformingproducts.HAZOPisbasedonatheorythatassumesriskeventsarecausedbydeviationsfromdesignoroperatingintentions.Identificationofsuchdeviationsisfacilitatedbyusingsetsof“guidewords”asasystematiclistofdeviationperspectives.ThisapproachisauniquefeatureoftheHAZOPmethodologythathelpsstimulatetheimaginationofteammemberswhenexploringpotentialdeviations.Asariskassessmenttool,HAZOPisoftendescribedas:AbrainstormingtechniqueAqualitativeriskassessmenttoolAninductiveriskassessmenttool,meaningthatitisa“bottom-up”riskidentificationapproach,wheresuccessreliesontheabilityofsubjectmatterexperts(SMEs)topredictdeviationsbasedonpastexperiencesandgeneralsubjectmatterexpertiseTheICHQ9Guideline,QualityRiskManagementendorsestheuseofHAZOP(amongstotherallowabletools)forpharmaceuticalqualityriskmanagement.InadditiontoitsutilityinQualityRiskManagement,HAZOPisalsocommonlyusedinriskassessmentsforindustrialandenvironmentalhealthandsafetyapplications.AdditionaldetailsontheHAZOPmethodologymaybefoundwithinIECInternationalStandard61882,HazardandOperabilityStudies(HAZOP)ApplicationGuide.ThisdocumentpresentssomeguidingprinciplesintheexecutionofHAZOPanalyses.Successfulapplicationofanyriskmanagementmodelrequiresthattoolsareusedinconcertwiththeoverallqualityriskmanagementprocess.ThisguidewillpresenttheprinciplesofHAZOPinthecontextoftheacceptedQualityRiskManagementprocessconsistingofRiskAssessment,RiskControl,RiskReviewandCommunicationandisintendedtocompliment(notreplaceorrepeat)theguidanceavailablewithinIECInternationalStandard61882.1.1DefinitionsWhendescribingtheHAZOPmethodology,thefollowingdefinitions1areuseful:Hazard-Potentialsourceofharm.Deviationsfromdesignoroperationalintentmayconstituteorproduceahazard.HazardsarethefocusofHAZOPstudies,anditshouldbenotedthatasinglehazardcouldpotentiallyleadtomultipleformsofharm.Definition:SYSTEMisthesubjectofariskassessmentandgenerallyincludesaprocess,product,activity,facilityorlogicalsystem.TrainingGuide:Hazard&OperabilityAnalysis(HAZOP)Page2of9Harm-Physicalinjuryordamagetothehealthofpeopleordamagetopropertyortheenvironment.Harmistheconsequenceofahazardoccurringandmaytakemanyforms:patientorusersafety,employeesafety,businessrisks,regulatoryrisks,environmentalrisks,etc.Risk-Combinationofprobabilityofoccurrenceofharmandtheseverityofthatharm.Inastrictsense,“risk”isnotalwaysexplicitlyidentifiedinHAZOPstudiessincethecoremethodologydoesnotrequireidentification(alsoreferredtoasrating)oftheprobabilityorseverityofharm.However,riskassessmentteamsmaychoosetoratethesefactorsinordertofurtherquantifyandprioritizerisksifneeded.1.2UsageHAZOPisbestsuitedforassessinghazardsinfacilities,equipment,andprocessesandiscapableofassessingsystemsfrommultipleperspectives:DesignoAssessingsystemdesigncapabilitytomeetuserspecificationsandsafetystandardsoIdentifyingweaknessesinsystemsPhysicalandoperationalenvironmentsoAssessingenvironmenttoensuresystemisappropriatelysituated,supported,serviced,contained,etc.Operationalandproc...